DTF vs. DTG

DTF vs. DTG in Fashion Transfers

In the dynamic world of fashion, customization and unique designs are becoming increasingly vital. Two major technologies that have emerged to meet these demands are Direct-to-Film (DTF) and Direct-to-Garment (DTG) printing. While both methods offer distinct advantages, DTF transfers have recently been gaining traction for their versatility and quality. This blog will explore the differences between DTF and DTG, with a particular focus on how DTF transfers are revolutionizing the fashion industry.

The Basics: What are DTF and DTG?

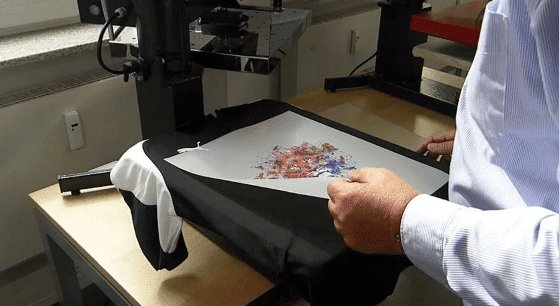

Direct-to-Garment (DTG) printing involves applying ink directly to the fabric using a specialized inkjet printer. This method is akin to how traditional paper printers work, but adapted for textiles. DTG is known for its ability to produce highly detailed and colorful prints, making it popular for creating custom t-shirts, hoodies, and other apparel items.

Direct-to-Film (DTF) printing, on the other hand, involves printing designs onto a special film, which is then transferred to the garment using heat. The process includes printing the design on the film, applying a powder adhesive, curing it, and then pressing it onto the fabric. This method has been making waves in the fashion industry due to its flexibility and the superior durability of the prints.

Why DTF Transfers Are Gaining Popularity

Versatility in Fabric Choice

One of the standout advantages of DTF transfers is their ability to work on a wide variety of fabrics. Unlike DTG, which works best on cotton or cotton-blend fabrics, DTF can be used on polyester, nylon, silk, and more. This opens up a plethora of options for fashion designers looking to experiment with different materials.

Vibrant and Durable Prints

DTF prints are known for their vibrant colors and sharp details. The process ensures that the designs are not only eye-catching but also long-lasting. The adhesive powder used in DTF transfers creates a strong bond with the fabric, making the prints resistant to washing and wear.

Cost-Effective for Small Batches

For small businesses or custom fashion designers, producing high-quality prints in small batches can be cost-prohibitive with traditional methods. DTF transfers offer a cost-effective solution, as the setup costs are lower, and there’s no need for expensive screens or plates. This makes it easier for emerging designers to create limited-edition runs without breaking the bank.

The DTF process is relatively straightforward and can be done with minimal equipment. This ease of use makes it accessible to a wider range of users, from professional fashion houses to DIY enthusiasts. The ability to produce high-quality prints without a steep learning curve is a significant advantage.

DTF in the Fashion Industry

Customization and Personalization

In the age of personalized fashion, consumers are looking for unique, one-of-a-kind pieces. DTF transfers allow designers to meet this demand by offering customizable designs that can be easily adjusted to suit individual preferences. Whether it’s a custom logo, a unique pattern, or a personalized message, DTF makes it possible to create bespoke fashion items with ease.

Sustainability Considerations

As the fashion industry grapples with its environmental impact, DTF transfers offer a more sustainable option. The process generates less waste compared to traditional screen printing and uses fewer resources. Additionally, the ability to print on demand reduces the need for large inventory stockpiles, minimizing waste from unsold products.

Innovation and Creativity

DTF transfers are pushing the boundaries of what’s possible in fashion design. The ability to print complex and detailed images opens up new creative avenues for designers. From intricate patterns to photorealistic images, the possibilities are endless. This innovation is driving a new wave of creativity in the fashion industry.

Comparing DTF and DTG: Which is Right for You?

While both DTF and DTG have their merits, choosing the right method depends on your specific needs and goals.

For Detailed, High-Quality Prints on Cotton Fabrics: DTG remains a strong choice. It excels in producing vibrant, high-resolution images on cotton garments, making it ideal for custom t-shirts and hoodies.

For Versatility and Durability Across Various Fabrics: DTF transfers take the lead. Their ability to adhere to multiple fabric types without compromising on quality makes them a superior choice for diverse fashion projects.

For Cost-Effective Small Batch Production: DTF is generally more cost-effective, especially for smaller runs. This can be particularly advantageous for independent designers or small businesses.

The Future of Fashion Transfers

As the fashion industry continues to evolve, technologies like DTF and DTG will play a crucial role in shaping its future. While DTG has been a staple for years, the rise of DTF transfers is opening new possibilities for designers and businesses alike. With its versatility, durability, and ease of use, DTF is poised to become a mainstay in the world of fashion customization.

Whether you're an established fashion house or an up-and-coming designer, exploring the potential of DTF transfers could unlock new levels of creativity and innovation. Embrace the future of fashion with DTF, and discover how this cutting-edge technology can transform your designs into wearable art.

Embrace the Future of Fashion with DTF Transfers

Ready to take your fashion designs to the next level? Discover the power of DTF transfers today! Whether you're a seasoned designer or just starting out, DTF offers unparalleled versatility, vibrant prints, and cost-effective solutions for your creative needs.

Don't miss out on this revolutionary technology. Enhance your collection with unique, high-quality designs that stand out and last. Explore the possibilities of DTF transfers and see how they can transform your fashion line.

Start your journey with DTF now and bring your vision to life! Contact us to learn more or place your first order.

Let’s create something extraordinary together.