How to use our Gang Sheet Builder and make DTF Transfer?

Direct-to-Film (DTF) printing is revolutionizing the custom apparel industry. This innovative process allows for vibrant, high-quality transfers that can be applied to a variety of fabrics. If you're new to DTF printing or looking to understand how DTF transfers are made, this guide will walk you through the entire process, from printing to transferring.

DTF Printing

DTF printing stands for Direct-to-Film printing. Unlike traditional printing methods, DTF doesn't require a pretreatment process. The designs are printed directly onto a special film using a DTF printer. This film is then transferred onto the garment using heat. The result is a durable, colorful, and high-resolution image that stands out on any fabric.

Heat Transfer Paper

Heat transfer paper is essential in the DTF process. It's a specialized paper designed to transfer printed designs onto fabrics. The heat transfer paper used in DTF printing is coated with a polymer that binds to the ink when heated, ensuring that the design adheres perfectly to the garment. The quality of the transfer paper plays a crucial role in the final outcome, affecting the vibrancy and durability of the print.

Iron Transfer Paper

Iron transfer paper, also known as iron-on transfer paper, is a simpler alternative for those looking to create custom designs at home. This type of transfer paper can be used with a standard home iron or a heat press. While it doesn't offer the same level of detail and durability as professional DTF printing, it's a great option for small projects and personal use. The process involves printing your design onto the iron transfer paper, placing it on the garment, and applying heat with an iron to transfer the image.

Direct to Film Printer

The heart of DTF printing is the Direct-to-Film printer. These printers are specifically designed to handle the unique requirements of DTF printing. They use specialized inks that adhere to the transfer film and produce vibrant, detailed images. Some DTF printers come with integrated white ink capabilities, allowing for prints on dark fabrics. Investing in a high-quality DTF printer is crucial for businesses looking to offer top-notch custom apparel.

Transfer Paper for Shirts

Transfer paper for shirts is specially designed to handle the unique requirements of fabric printing. It ensures that the design is transferred evenly and adheres well to the fabric. There are different types of transfer paper depending on the fabric type and the desired finish. For instance, there are papers designed for dark fabrics, light fabrics, and even specialty papers for different textures and finishes.

The DTF Transfer Process

Design Preparation: The process starts with creating or selecting a design. This design is then digitally prepared for printing. The design software ensures that the image will print correctly on the DTF film, including any necessary color adjustments and white ink layering.

Printing: The prepared design is printed onto the DTF film using the Direct-to-Film printer. The printer applies a layer of ink to the film, followed by a layer of white ink if the design requires it. This white layer ensures that the colors stand out, even on dark fabrics.

Powder Application: After printing, a special adhesive powder is applied to the film while the ink is still wet. This powder will help the design adhere to the fabric during the heat transfer process. The film is then cured to set the powder and ink.

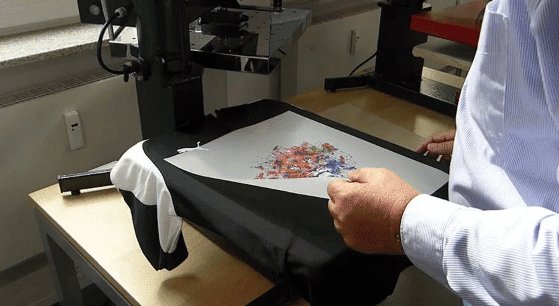

Heat Transfer: The printed and powdered film is placed onto the garment. Using a heat press, the film is pressed onto the fabric at a specific temperature and pressure. This heat activates the adhesive powder, bonding the design to the fabric.

Peeling: Once the heat press cycle is complete, the film is carefully peeled away, leaving the design transferred onto the garment. The result is a vibrant, durable print that can withstand multiple washes without fading or cracking.

Why Choose DTF Printing?

DTF printing offers several advantages over traditional methods. It allows for high-quality, full-color prints on a variety of fabrics, including cotton, polyester, and blends. The prints are durable and flexible, making them ideal for apparel that needs to withstand regular wear and washing. Additionally, DTF printing is a cost-effective solution for producing custom designs, as it eliminates the need for screens or plates, reducing setup costs and time.

For high-quality DTF supplies and printing services, visit DTF Fashion. Their wide range of products and expertise can help you achieve the best results in your custom apparel projects.

Ready to Elevate Your Custom Apparel?

Discover the power of DTF printing with DTF Fashion. Whether you're a seasoned professional or just starting out, our high-quality supplies and expert services will help you create stunning, durable designs that stand out.

Visit our website today to explore our wide range of products and take your custom apparel projects to the next level. Don't wait—transform your designs with DTF Fashion now