Article: What is a DTF Transfer?

What is a DTF Transfer?

- Versatility

One of the primary advantages of DTF transfers is their versatility. They can be used on a wide range of fabrics, making them ideal for producing custom apparel, accessories, and promotional items. Unlike DTG printing, which works best on cotton, DTF transfers can be applied to polyester, nylon, silk, and more, offering greater flexibility for designers and manufacturers.

- High-Quality Prints

DTF transfers produce high-resolution, vibrant prints that are durable and resistant to washing and fading. The colors are vivid, and the details are sharp, making them perfect for intricate designs and logos. The prints also have a soft hand feel, ensuring comfort when worn.

- Cost-Effective

For small to medium-sized print runs, DTF transfers can be more cost-effective than traditional screen printing. There is no need for expensive setup costs, making it an attractive option for businesses looking to produce limited edition items or custom designs without a large upfront investment.

- Ease of Use

The DTF transfer process is straightforward and requires minimal training. With the right equipment, even beginners can achieve professional-quality results. This ease of use makes DTF printing accessible to small businesses, hobbyists, and entrepreneurs looking to enter the custom apparel market.

- Environmentally Friendly

DTF transfers use less water and produce less waste compared to traditional printing methods. This eco-friendly aspect is increasingly important as consumers and businesses become more conscious of their environmental impact.

- Speed

The DTF printing process is relatively quick, allowing for fast turnaround times. This speed is crucial for businesses that need to meet tight deadlines or handle large orders efficiently.

Previous Private DTF Transfers You Can Trust Have you read our blog post titled? Please click here

What Equipment Do I Need To Create DTF Prints?

To start creating DTF prints, you will need the following equipment:

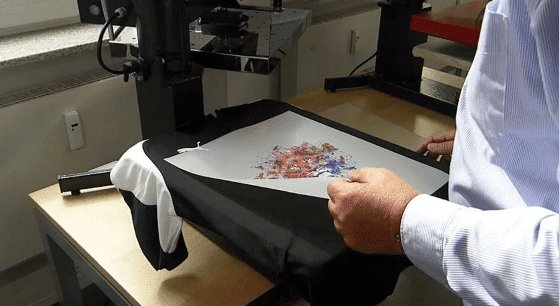

- DTF Printer

A specialized DTF printer is essential for producing high-quality prints. These printers are designed to handle the specific requirements of DTF printing, including the ability to print on PET films and use specialized inks. While some DTG printers can be adapted for DTF printing, dedicated DTF printers generally offer better performance and reliability.

- PET Films

PET (Polyethylene Terephthalate) films are the substrates onto which the designs are printed. These films are specifically coated to accept the DTF inks and provide a smooth transfer to the fabric. High-quality PET films are crucial for achieving sharp, detailed prints.

- DTF Inks

DTF inks are specially formulated to adhere to the PET films and provide vibrant, durable prints. These inks are typically pigment-based and offer excellent color reproduction and durability.

- Hot Melt Powder

Hot melt powder is applied to the printed film to act as an adhesive when transferring the design to the fabric. This powder ensures that the print adheres securely and evenly to the material. The powder comes in different grades, suitable for various types of fabrics.

- Heat Press

A heat press is used to transfer the printed film to the fabric. The heat press applies heat and pressure to activate the hot melt powder, bonding the design to the material. Heat presses come in various sizes and configurations, from small desktop models to larger industrial machines.

- Curing Oven or Heat Gun

After applying the hot melt powder, the film needs to be cured to set the adhesive. This can be done using a curing oven or a heat gun. Proper curing is essential to ensure the durability and washability of the prints.

- Software

Design software is used to create and prepare the digital designs for printing. Popular design software options include Adobe Illustrator, CorelDRAW, and Photoshop. Additionally, RIP (Raster Image Processor) software is often used to manage the printing process, ensuring accurate color reproduction and print quality.

Additional Tools and Accessories